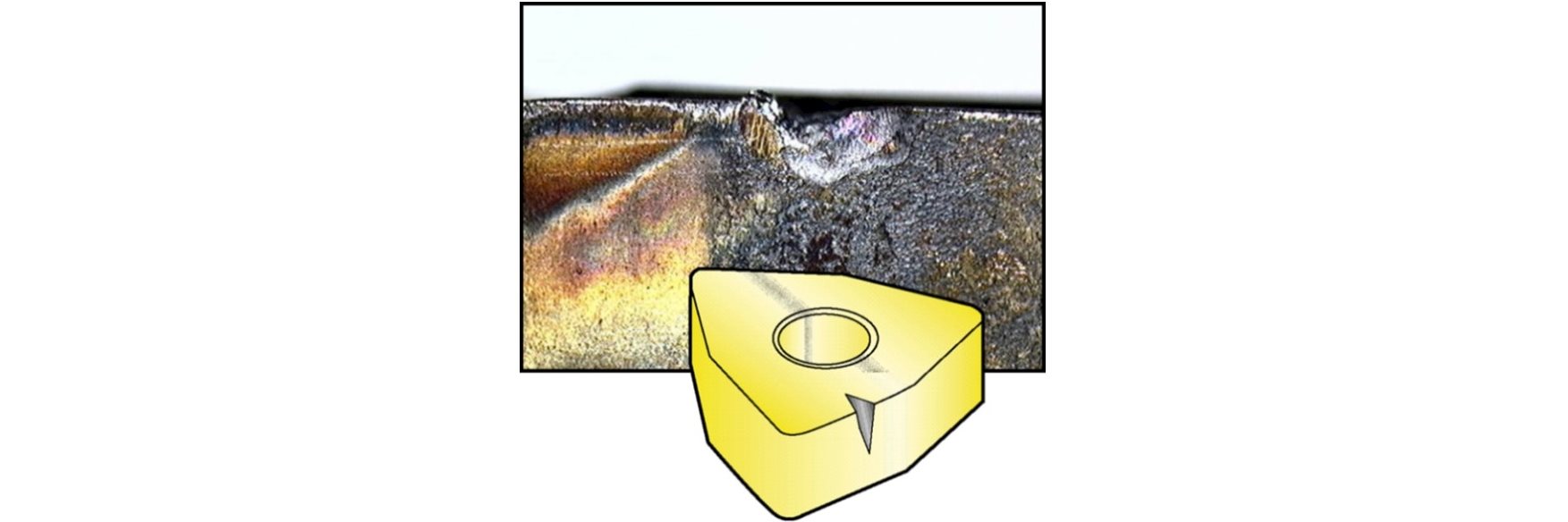

Notch Wear On Cutting Tools . Web abrasive wear is usually the primary cause of flank wear, notch wear, and nose radius wear, and as such is the often the form of. Web notch wear is a wear mechanism that forms on the flank and rake of a turning insert cutting edge at the “depth of cut line” (see picture) due to. The reason of such type of wear is mechanical contact between. Let’s go through and see what each type of wear is and what causes it. Abrasive wear is the normal. Flank face wear is caused by abrasion between the workpiece and the flank face. Web notching wear is found at the outer end of principal flank.

from www.secotools.com

Web notching wear is found at the outer end of principal flank. Web notch wear is a wear mechanism that forms on the flank and rake of a turning insert cutting edge at the “depth of cut line” (see picture) due to. Web abrasive wear is usually the primary cause of flank wear, notch wear, and nose radius wear, and as such is the often the form of. Let’s go through and see what each type of wear is and what causes it. The reason of such type of wear is mechanical contact between. Flank face wear is caused by abrasion between the workpiece and the flank face. Abrasive wear is the normal.

TOOL WEAR PATTERNS IN MACHINING

Notch Wear On Cutting Tools Web notching wear is found at the outer end of principal flank. The reason of such type of wear is mechanical contact between. Abrasive wear is the normal. Flank face wear is caused by abrasion between the workpiece and the flank face. Web notching wear is found at the outer end of principal flank. Web abrasive wear is usually the primary cause of flank wear, notch wear, and nose radius wear, and as such is the often the form of. Let’s go through and see what each type of wear is and what causes it. Web notch wear is a wear mechanism that forms on the flank and rake of a turning insert cutting edge at the “depth of cut line” (see picture) due to.

From smart-toolgroup.com

How to cut a notch in wood with a multitool Notch Wear On Cutting Tools Web notching wear is found at the outer end of principal flank. Web abrasive wear is usually the primary cause of flank wear, notch wear, and nose radius wear, and as such is the often the form of. Flank face wear is caused by abrasion between the workpiece and the flank face. Let’s go through and see what each type. Notch Wear On Cutting Tools.

From www.slideserve.com

PPT Theory of cutting Tool wear PowerPoint Presentation, free Notch Wear On Cutting Tools Web abrasive wear is usually the primary cause of flank wear, notch wear, and nose radius wear, and as such is the often the form of. Web notch wear is a wear mechanism that forms on the flank and rake of a turning insert cutting edge at the “depth of cut line” (see picture) due to. Flank face wear is. Notch Wear On Cutting Tools.

From smart-toolgroup.com

How to cut a notch in stud work with a multitool Notch Wear On Cutting Tools Flank face wear is caused by abrasion between the workpiece and the flank face. Abrasive wear is the normal. The reason of such type of wear is mechanical contact between. Web abrasive wear is usually the primary cause of flank wear, notch wear, and nose radius wear, and as such is the often the form of. Web notch wear is. Notch Wear On Cutting Tools.

From www.researchgate.net

10. Types wear on cutting tools (adapted from Sandvik® [12]) Download Notch Wear On Cutting Tools Web abrasive wear is usually the primary cause of flank wear, notch wear, and nose radius wear, and as such is the often the form of. Abrasive wear is the normal. Flank face wear is caused by abrasion between the workpiece and the flank face. Web notch wear is a wear mechanism that forms on the flank and rake of. Notch Wear On Cutting Tools.

From www.researchgate.net

Cutting tool wear forms in orthogonal metal cutting. Download Notch Wear On Cutting Tools Flank face wear is caused by abrasion between the workpiece and the flank face. Web notching wear is found at the outer end of principal flank. Abrasive wear is the normal. Let’s go through and see what each type of wear is and what causes it. Web abrasive wear is usually the primary cause of flank wear, notch wear, and. Notch Wear On Cutting Tools.

From www.youtube.com

How To Cut a Wide Notch Using Simple Tools YouTube Notch Wear On Cutting Tools Flank face wear is caused by abrasion between the workpiece and the flank face. Web notching wear is found at the outer end of principal flank. The reason of such type of wear is mechanical contact between. Let’s go through and see what each type of wear is and what causes it. Web notch wear is a wear mechanism that. Notch Wear On Cutting Tools.

From www.weinotools.com

PCD Notching Tools, CBN Notching Tools, Carbide Notching Tools Notch Wear On Cutting Tools The reason of such type of wear is mechanical contact between. Let’s go through and see what each type of wear is and what causes it. Abrasive wear is the normal. Web notching wear is found at the outer end of principal flank. Flank face wear is caused by abrasion between the workpiece and the flank face. Web notch wear. Notch Wear On Cutting Tools.

From www.buildeazy.com

How to Cut a Notch in Wood Using a Variety of Tools BuildEazy Notch Wear On Cutting Tools Let’s go through and see what each type of wear is and what causes it. Abrasive wear is the normal. Web abrasive wear is usually the primary cause of flank wear, notch wear, and nose radius wear, and as such is the often the form of. Web notching wear is found at the outer end of principal flank. Web notch. Notch Wear On Cutting Tools.

From www.youtube.com

Motorized Notch Cutter Manufacturers; Suppliers & Exporters YouTube Notch Wear On Cutting Tools The reason of such type of wear is mechanical contact between. Let’s go through and see what each type of wear is and what causes it. Web notch wear is a wear mechanism that forms on the flank and rake of a turning insert cutting edge at the “depth of cut line” (see picture) due to. Abrasive wear is the. Notch Wear On Cutting Tools.

From sawshub.com

How to Cut a Notch in Wood SawsHub Notch Wear On Cutting Tools Web notch wear is a wear mechanism that forms on the flank and rake of a turning insert cutting edge at the “depth of cut line” (see picture) due to. Let’s go through and see what each type of wear is and what causes it. Web notching wear is found at the outer end of principal flank. Flank face wear. Notch Wear On Cutting Tools.

From www.mdpi.com

Materials Free FullText Wear Mechanisms and Notch Formation of Notch Wear On Cutting Tools Flank face wear is caused by abrasion between the workpiece and the flank face. Web notch wear is a wear mechanism that forms on the flank and rake of a turning insert cutting edge at the “depth of cut line” (see picture) due to. Abrasive wear is the normal. Web notching wear is found at the outer end of principal. Notch Wear On Cutting Tools.

From www.indiamart.com

CNC Notching Cutting Tool Carbide 7mm at Rs 399/piece Notching Tools Notch Wear On Cutting Tools Web notch wear is a wear mechanism that forms on the flank and rake of a turning insert cutting edge at the “depth of cut line” (see picture) due to. Let’s go through and see what each type of wear is and what causes it. The reason of such type of wear is mechanical contact between. Web notching wear is. Notch Wear On Cutting Tools.

From www.secotools.com

TOOL WEAR PATTERNS IN MACHINING Notch Wear On Cutting Tools Web notch wear is a wear mechanism that forms on the flank and rake of a turning insert cutting edge at the “depth of cut line” (see picture) due to. Web notching wear is found at the outer end of principal flank. Abrasive wear is the normal. The reason of such type of wear is mechanical contact between. Web abrasive. Notch Wear On Cutting Tools.

From www.canadianmetalworking.com

Identifying tool wear Notch Wear On Cutting Tools Web notch wear is a wear mechanism that forms on the flank and rake of a turning insert cutting edge at the “depth of cut line” (see picture) due to. Flank face wear is caused by abrasion between the workpiece and the flank face. Web abrasive wear is usually the primary cause of flank wear, notch wear, and nose radius. Notch Wear On Cutting Tools.

From www.researchgate.net

a Top view of crater wear and nose profile and b flank wear land and Notch Wear On Cutting Tools Web abrasive wear is usually the primary cause of flank wear, notch wear, and nose radius wear, and as such is the often the form of. Flank face wear is caused by abrasion between the workpiece and the flank face. Web notch wear is a wear mechanism that forms on the flank and rake of a turning insert cutting edge. Notch Wear On Cutting Tools.

From www.mech4study.com

Tool Wear Flank Wear, Crater Wear and Nose Wear Mechanism Mech4study Notch Wear On Cutting Tools Let’s go through and see what each type of wear is and what causes it. Web notching wear is found at the outer end of principal flank. Abrasive wear is the normal. Web notch wear is a wear mechanism that forms on the flank and rake of a turning insert cutting edge at the “depth of cut line” (see picture). Notch Wear On Cutting Tools.

From sawshub.com

How to Cut a Notch in Wood SawsHub Notch Wear On Cutting Tools Let’s go through and see what each type of wear is and what causes it. Web abrasive wear is usually the primary cause of flank wear, notch wear, and nose radius wear, and as such is the often the form of. Web notch wear is a wear mechanism that forms on the flank and rake of a turning insert cutting. Notch Wear On Cutting Tools.

From www.indiamart.com

CNC Notching Cutting Tool Carbide 4.5 mm at Rs 230/piece Notching Notch Wear On Cutting Tools The reason of such type of wear is mechanical contact between. Web notch wear is a wear mechanism that forms on the flank and rake of a turning insert cutting edge at the “depth of cut line” (see picture) due to. Abrasive wear is the normal. Flank face wear is caused by abrasion between the workpiece and the flank face.. Notch Wear On Cutting Tools.